In the world of automotive repair efficiency and safety are important. One of the essential tools that greatly contribute towards these aspects of the gearbox is lifting Jack. You need to know that the jacks are indispensable in automotive repair workshops providing the importance of audience stability for lifting and handling heavy gearboxes.

Understanding Gearbox Lifting Jacks

Types of Jacks:

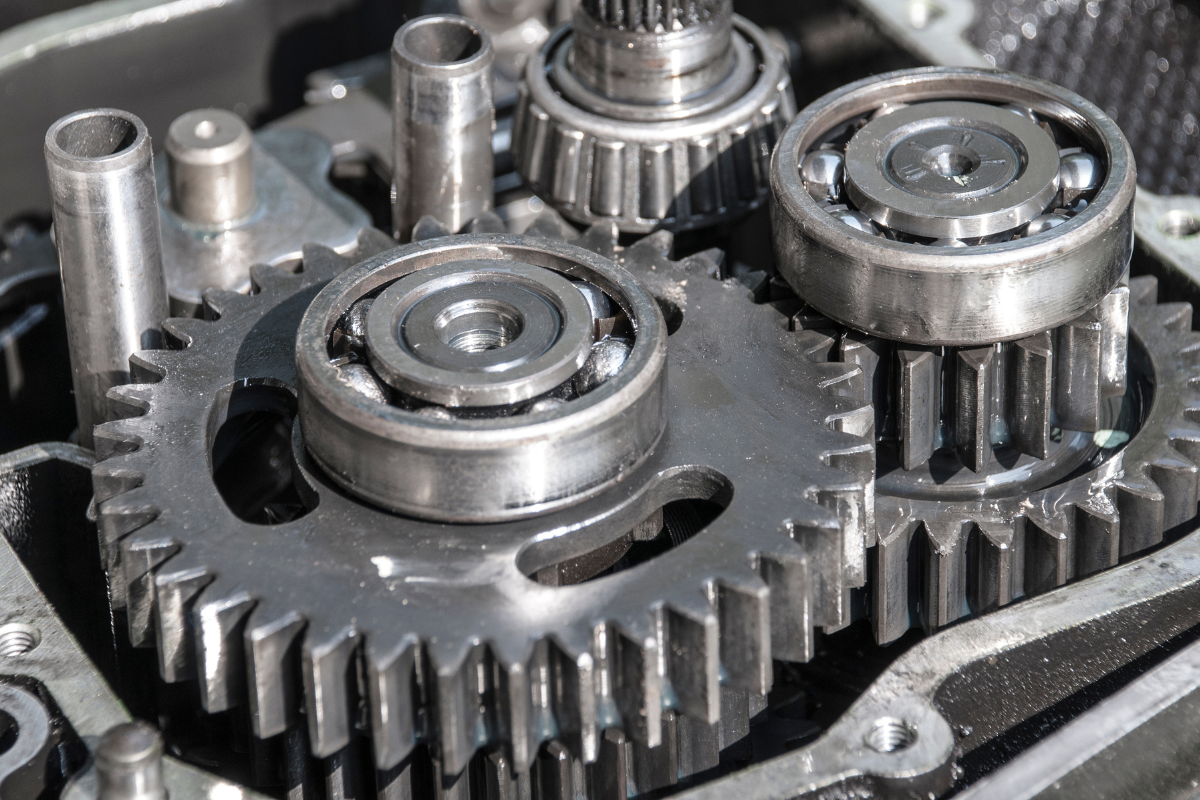

Hydraulic jacks are widely used in automotive repair shops because of their efficiency and ease of use. They operate using the fluid to generate force in it to lift your heavy gearboxes. They are capable of lifting very heavy gear boxes with minimum effort. You need to know the systems provide smooth and controlled lowering. The mechanical jacks use mechanical advantage typically through screw mechanisms or gears to lift the gear boxes. It often is more durable and less prone to leaks as compared to hydraulic jacks. They are also very easy to maintain due to the absence of hydraulic components.

Applications:

The gearbox lifting jacks are basically used in removing and installing transmission in vehicles. You can even facilitate access to the clutch assembly by supporting gearboxes. Furthermore you can use it to lift and support gear boxes during different maintenance tasks.

Benefits of Using a Gearbox Lifting Jack

Safety and Stability:

one of the best parts about using a gearbox lifting Jack is the enhanced safety that it provides. The lifting and handling of heavy girl walks can be extremely hazardous posing several risks of injury to technicians and damage to your vehicle. You need to know that the gearbox lifting jacks offer you stable support reducing the risks greatly.

Efficiency:

The gearbox lifting jacks can streamline the process of removing and installing your gearboxes. By reducing the need for manual lifting the jacks save you a lot of time and effort allowing experts to just focus on the actual repair work. The increased efficiency translates to quick turn around times and even improved productivity in the workshop.

Versatility:

Gearbox lifting jacks are especially designed to accommodate different vehicle types and sizes from small cars to large trucks and even commercial vehicles. This versatility makes them a perfect tool in any automotive repair shop ensuring that you can handle a huge range of vehicles with a single piece of equipment.

Step-by-Step Guide to Using a Gearbox Lifting Jack

Preparation

Before using the gearbox lifting Jack you need to start by inspecting the gearbox lifting Jack for any signs of damage or defects. You need to check the hydraulic fluid levels if you are using a hydraulic Jack and ensure that all the mechanical parts are in good working condition. Regular maintenance and inspection help you prevent accidents and equipment failure. Just ensure that the workspace is clear of obstacles and of course properly ventilated. A clean and organized workspace reduces the risk of accidents and allows for easy movement around your vehicle.

Positioning the Jack

You need to place the gearbox lifting box under the vehicle in a secure unstable position. You just need to refer to the vehicle service manual for the recommended lifting points to avoid damaging any components. Furthermore you need to adjust the jack’s height to align with the gearbox mounting points. Just ensure proper alignment is critical for stability during the lifting process.

Lifting the Gearbox

You can use the jacks handle or hydraulic control to gradually raise the gearbox. You can avoid sudden movements and lift slowly to maintain control and of course stability. You need to pay close attention to the alignment and balance of the gearbox throughout the lifting process. You must constantly monitor the lifting process to ensure stability. If any instability or misalignment occurs you need to lower the gearbox and reposition the Jack before you continue.

Supporting the Gearbox

Once the gearbox is lifted to the desired height it must be securely supported. You can secure the gearbox using the appropriate support stand or block. You must double check the stability of the setup to ensure that the gearbox is completely supported and will not shift during the repair process. Before proceeding with any repair or maintenance tasks just to ensure that all the safety measures are completely in place. You can verify that the supports are stable and the gearbox is securely held in position.

Lowering the Gearbox

After you complete the important repairs or replacements the gearbox needs to be safely lowered. You need to slowly lower the gearbox back into the position using the jacks handle or hydraulic control. As with lifting, gradually lowering helps you maintain control and stability. You can carefully remove the gearbox lifting Jack and support once the gearbox is securely placed. Just ensure that there is no component left unsupported before fully retracting your Jack.

Safety Precautions

Weight Capacity:

you should never exceed the maximum weight capacity of your gearbox lifting Jack. Every Jack is specially designed to lift a specific weight and exceeding the limit can cause the Jack to fail potentially resulting in severe injury or damage to your vehicle. You must always refer to the manufacturer specifications and guidelines to ensure that they are within the safe operating limits.

Stability:

you must ensure the vehicle is on a level surface before using the gearbox lifting Jack. An uneven surface can cause instability increasing the risk of your vehicle shifting or the Jack tipping over. Furthermore you can use the wheel chokes to prevent the vehicle from rolling. Properly choking the wheels is an essential safety step that will help you secure the vehicle in place during the lifting process.

Personal Protective Equipment (PPE):

It is very important for you to wear appropriate personal protective equipment when operating a gearbox lifting Jack. Your kit must include gloves to protect your hands from injuries and abrasion safety glasses to protect your eyes from debris and potential splashes of hydraulic fluid and suitable clothing that covers your arms and legs to prevent scrapes and cuts. Proper protection ensures that you are protected from common hazards linked with automotive repair work.

Maintenance and Storage

Regular Inspections:

To ensure the long-term functionality and safety of your gearbox lifting Jack you need to conduct regular inspections. You need to check for any leaks and hydraulic jacks wherein mechanical components and also overall structural integrity. You must inspect the moving parts for any signs of damage or excessive wear. Regular inspections help potential issues before they become major ones ensuring that our equipment remains in optimum condition.

Cleaning and Lubrication:

You need to keep the gearbox lifting Jack clean for its proposition. Dirt and debris can interfere with the moving parts causing wear and reducing efficiency. You must lubricate the moving parts as recommended by the manufacturer. Proper lubrication reduces friction and wear prolonging the life of your jacket ensuring smooth operation.

Storage:

You must know that storing the gearbox lifting Jack in a dry and secure location away from moisture and extreme temperatures is really important. Moisture can cause rust and corrosion Especially on metal components while extreme temperatures can impact the hydraulic fluid performance and the overall integrity of your Jack. A well maintained storage environment ensures that your track remains in a good condition and ready for use whenever needed.

So above all you need to know that investing in high quality gearbox lifting Jack and maintaining it properly can greatly impact the effect and efficiency of automotive repair operations. The technicians equipped with the right tools and knowledge can perform the tasks more effectively resulting in better service for your customers and safe working environment. By just focusing on safety and proper training you can maximize the benefits of using gearbox lifting jacks and ensure long term success.