It is a troublesome task to manage and maintain tires of large vehicles, particularly in public space where effectiveness and safety are of prime importance. A commercial vehicle tire changer is a critical equipment for any service center or mechanic shop that deals with heavy goods vehicles.

Importance of Using a Commercial Vehicle Tire Changer

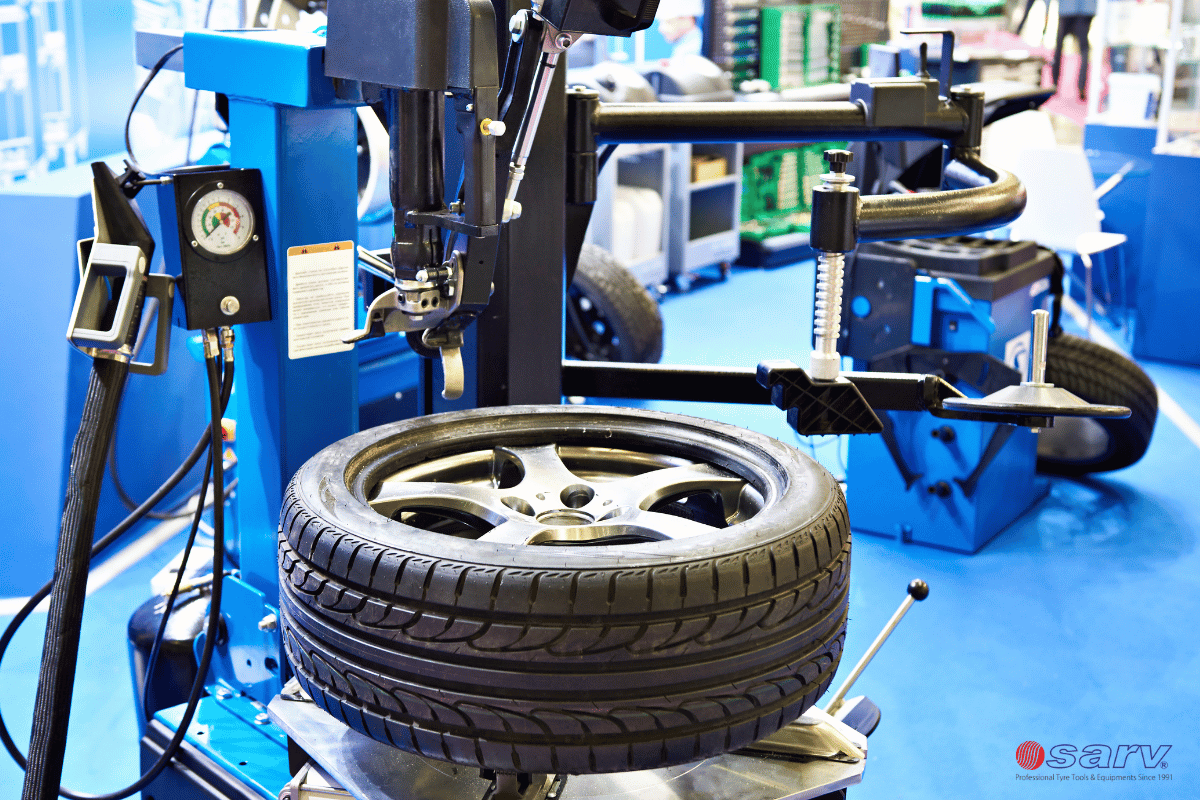

Commercial vehicle tire changers are specifically devised to handle the problems faced by larger tires found on trucks, trailers, bus, and other heavy vehicles. In comparison to the standard tire changers, these machines are furnished with sturdy features that guarantees a secure and systematic lifting and taking down of oversized tires. This unique tool helps a great deal in tire-changing process smoothly, minimising the risk of damage that can be caused to both tires and wheels.

Benefits of Using the Correct Equipment

The advantages of using the right tire changer are:

- Efficiency: Commercial tire changers are designed to handle heavy-duty tires efficiently, helping to reduce downtime in hectic situations without affecting productivity.

- Safety: These machines are crafted with specific features to safeguard the operators from any injury that might occur while handling heavy tires manually.

- Accuracy: First-rate tire changers are equipped to ensure safety and smooth execution, ensuring perfect fitting and equilibrium.

- Durability: Commercial tire-changers are built with durable materials to increase their endurance, ensuring they are resilient towards the harshness of heavy use.

- Cost-Effectiveness: By investing in the right machinery, businesses can minimise the possibility of costly blunder, tire damage, and extended service time.

To conclude, employing and using a commercial tire-changer is convenient and a profitable asset at ensuring the efficiency and safety of any operation involving heavy vehicles.

Safety Precautions

Safety must be the highest priority before proceeding towards the tire-changing process. Some safety measures to be followed are:

- Wear Safety Gear: Wearing safety gloves and glasses shield us from sharp objects and scraps. It is also recommended to wear proper footwear to prevent slipping and potential damage caused by heavy machines.

- Maintain a Clean Workspace: It is advised to keep the working space tidy, free from any hindrance and also well-lighted. An obstruction-free work area reduces the risk of accidents and provides better mobility.

It is crucial to have the perfect equipment for an effective tire-changing process. Let us go through the essential and optional tools breakdown:

Tools and Equipment Needed

Essential Tools

- Commercial Vehicle Tire Changer: Especially made to handle heavy-duty tires effectively, reducing injury or any kind of damage.

- Air Compressor: An indispensable tool required in modern industrial operation, such as inflating tires and supplying power to air-powered tools.

- Bead Breaker: It plays a key role in separating the tire from its rim by breaking the seal between the tire bead and rim, ensuring easy removal.

Optional Tools

- Tire Balancer: A machine that ensures a balance between wheel alignment and tire weight to enhance vehicle performance and tire longevity.

- Tire Lubricant: Applying it with a brush evenly on both rim and tire enables smooth mounting and demounting, reducing friction and corrosion.

Preparing the Tire and Rim

A crucial step to be followed before changing the tire is to prepare both the tire and rim:

- Inspect for Damage: it is necessary to examine carefully, both rim and tire, for any sign of damage, like cuts, punctures, holes, or bent rims. Considering these issues beforehand can help to avoid upcoming obstacles.

- Remove Debris: Keep the surface of the tire and rim speckless when trying to reinstall a tire. Ensure that there is no dirt or debris for an effective seal and fit.

- Deflate the Tire: To deflate a tire properly press down on the valve system using a pressure gauge at the end. This is an important step for safe removal of the tire from the rim.

- Clean the Rim: Tidy up the rim spotlessly to remove old tire sealant, rust, or sludge. It is essential to keep the rim squeaky clean before mounting a tire to ensure a perfect seal.

If followed properly, these precautionary steps can help you facilitate a smooth and safe tire-changing process.

Using the Commercial Vehicle Tire Changer

A number of specific steps are involved while changing tires using a commercial vehicle tire changer. Here’s a detailed guide to ensure a smooth and safe process.

Step 1: Position the Tire on the Machine

- Place the Tire and Rim: Position the rim and tire cautiously onto the tire mounter. Be certain that the rim is firmly planted in the centre of the machine.

- Align Properly: Ensuring that the tire is perfectly aligned with the machine’s mounting and demounting heads is crucial for a risk-free operation.

Step 2: Breaking the Bead

- Use the Bead Breaker: Follow the instructions properly to operate the bead breaker. Install the tool opposite to the tire sidewall, making sure it is connected to the bead area.

- Effective Techniques: In order to break the bead, apply a constant amount of pressure continuously as extreme force can damage the tire or rim. If it doesn’t break, reposition the bead breaker a little and try again.

Step 3: Removing the Old Tire

- Utilize the Levers and Tools: Make full utilisation of the tire-changer levers to raise the tire over the rim’s border. Position the demounting head to help with the transfer.

- Careful Removal: Very carefully remove the tire from the rim without applying excessive pressure as it can damage the rim or the tire changer’s parts.

Step 4: Mounting the New Tire

- Position the New Tire: After being sure that the new tire is perfectly positioned along the rim, place it on the machine’s mounting head.

- Apply Tire Lubricant: Make apt use of the tire lubricant and apply it fairly around the bead of the tire to enable effortless mounting and prevent any damage in between.

- Mount the Tire: Turn on the machine to fit the tire onto the rim, ensuring it sticks properly without breaking it open.

Step 5: Inflating the Tire

- Inflate Using Air Compressor: Attach the air compressor and inflate the new tire to the recommended pressure, as instructed by the manufacturer.

- Check Bead Seating: after successfully completing the inflation process, examine the beads to ensure it is fixed properly. Inspect carefully for unevenness.

- Inspect for Leaks: Check for leaks by spreading soapy water over the inflated tire. Formation of bubbles is an indication of possible leaks that needs to be handled.

You can efficiently use a commercial tire-changer by following these instructions. These steps also ensure a safe and effective tire-changing process.

Tips for Effective Tire Changing

Changing a tire successfully in commercial settings requires conscientiousness and efficiency. Here are some important tips to upgrade your tire-changing skills.

Proper Machine Settings

- Adjust for Tire Size and Type: Before starting the process, be aware about the type of tire you are working with. Always make sure to check that the tire-changer is set up to the required size, if not adjust the mounting head height and other machine settings too.

- Calibrate the Machine: A routine sweep is must to see that the machine is calibrated. Poor or wrong configuration might damage the tires or rims during the process.

- Inspect Machine Condition: Ensure the tire changer is functioning properly before using it. Look for worn parts, sufficient lubrication, and any signs of defect.

Using Tire Lubricant

- Benefits of Tire Lubricant: To reduce friction during mounting and demounting, use suitable lubricant as it smoothens the process and prevent potential damage.

- Proper Application Techniques: The lubricant must be applied uniformly along the tire bead and rim edge before mounting. Proper lubrication ensures that the tire fits into the rim with ease without applying extreme pressure.

Handling Large or Difficult Tires

- Dealing with Oversized Tires: A tire changer is specifically constructed for heavy-duty applications, for instance working with larger tires. It must be seen to that the machine is rated for the size you’re handling.

- Managing Difficult Bead Seating: Some tires that are difficult to mount can be seated through careful inflation and proper lubrication. Start inflating the tire at a low pressure and then slowly increase it while checking bead alignment.

- Alignment Techniques: Inspect visually or with measuring tools to ensure that the tire is centred on the rim before inflating. If not seated, then bounce gently to fit it.

By adhering to these rules in the tire-changing process, you can enhance efficiency, safety, and overall performance, especially when handling large tires.

Common Problems and Solutions

In spite of taking precautions and applying correct techniques, challenges can occur during the process. Here’s some tips to troubleshooting common issues and their solutions.

Troubleshooting Bead Seating Issues

Identifying Bead Seating Problems

- Uneven Bead Seating: The gap between the bead and rim is an indication of uneven seating. Examine carefully for gaps.

- Air Leaks: Use soapy water to check for air holes. Pay close attention to the hissing sound as it verifies air escaping the bead area.

Solutions for Proper Seal

- Adjust Tire Pressure: Adjust the pressure in the tire by starting with lower pressure and then increase it steadily while checking for proper beat seating. Sometimes, a sudden increase in pressure can help pop the bead into place.

- Use Lubricant: Apply tire lubricant in sufficient quantity to the rim and bead. It helps in reducing friction and proper seating of the tire.

- Repositioning: In case the tire isn’t seated properly, deflate and reposition it on the rim, ensuring it is centred before reinflating.

Dealing with Machine Malfunctions

Common Issues with Tire Changers

- Inconsistent Mounting/Demounting: Worn out machine parts or improper settings can create problems while mounting and demounting.

- Hydraulic Issues: Problems with hydraulic pressure can prevent the machine from functioning correctly.

How to Resolve Malfunctions

- Check Settings: Always check if the machine settings are suitable for the tire size. If not, adjust it to appropriate settings as per your requirement.

- Inspect Components: Routine checkup for worn out components or tools, such as levers, heads, and hydraulic systems is compulsory for effective performance.

Maintenance and Professional Repair

- Scheduled Maintenance: To prevent breakdowns and extend longevity of the machine, ensure routine checkups and servicing, following the manufacturer’s maintenance schedule.

- When to Seek Help: Immediately contact a professional technician if there are specific malfunctions, like hydraulic leaks. If troubleshooting is unable to fix the problem, address the complications to avoid further damage.

Being cautious and dynamic in approach while identifying issues and knowing how to address them can maintain efficiency and durability of your tire-changing equipment.

Maintenance and Care

For optimal performance and extended life of your commercial vehicle tire changer, ensure proper care and maintenance. Here’s how to keep your equipment in top condition.

Importance of Regular Maintenance

It is absolutely essential to have routine maintenance to avoid breakdowns, increase the life span of the machine, and ensure safety during the process. Regular checks can catch minor issues before they escalate into major problems.

Routine Checks and Maintenance Tasks

- Visual Inspections: Inspect frequently for any signs of damaged or worn-out components, such as levers, mounting heads, and hydraulic systems.

- Lubrication: To minimise the danger of rusting and maximise the smoothness of an operation, keep moving parts lubricated according to the manufacturer’s recommendations.

- Hydraulic System Maintenance: Look for leakage or holes in hoses and connections. Check hydraulic fluid levels and replace fluids as needed.

- Electrical Components: Be certain that all electrical connections are tight and functioning properly, without any corrosion or wear signs.

Cleaning and Storing the Equipment

Proper Cleaning Procedures

- After Use: After each use, clean the tire changer thoroughly to remove dust, dirt, debris or tire lubricant. It is best to use a soft cloth and mild cleaning agents to prevent any damage to the surface.

- Check for Debris: be absolutely sure to clean the machine spotless, leaving no broken fragments or dust particles in the moving parts, that can lead to malfunctions.

Tips for Storing the Tire Changer

- Environment: To prevent the tire changer from rust and corrosion, it is advised to store it in a dry, clean environment. Also be sure to keep the machine away from places with extreme temperature and moisture.

- Covering: In an open area or less controlled environment, the machine must be kept shielded from dust using a protective cover.

- Disconnect Power: Remember to disconnect the power source when the machine is not in use to prevent accidental activation.

Conclusion

Recap of Key Tips

To summarise, using a commercial vehicle tire changer efficiently involves:

- Proper Setup: Regulate machine settings and adjust the alignment.

- Lubrication: Use a correct and adequate quantity of tire lubricant for easier mounting.

- Troubleshooting: Immediately sort out the bead seating issues and machine malfunctions.

- Regular Maintenance: A routine sweep, proper cleaning and timely maintenance service must be conducted.

Emphasis on Safety and Proper Techniques

It must be a priority to keep yourself safe throughout the whole tire-changing process by wearing appropriate safety gear and following correct techniques. With little maintenance and best practices, you can upgrade the efficiency, safety, and overall performance of your tire operations.